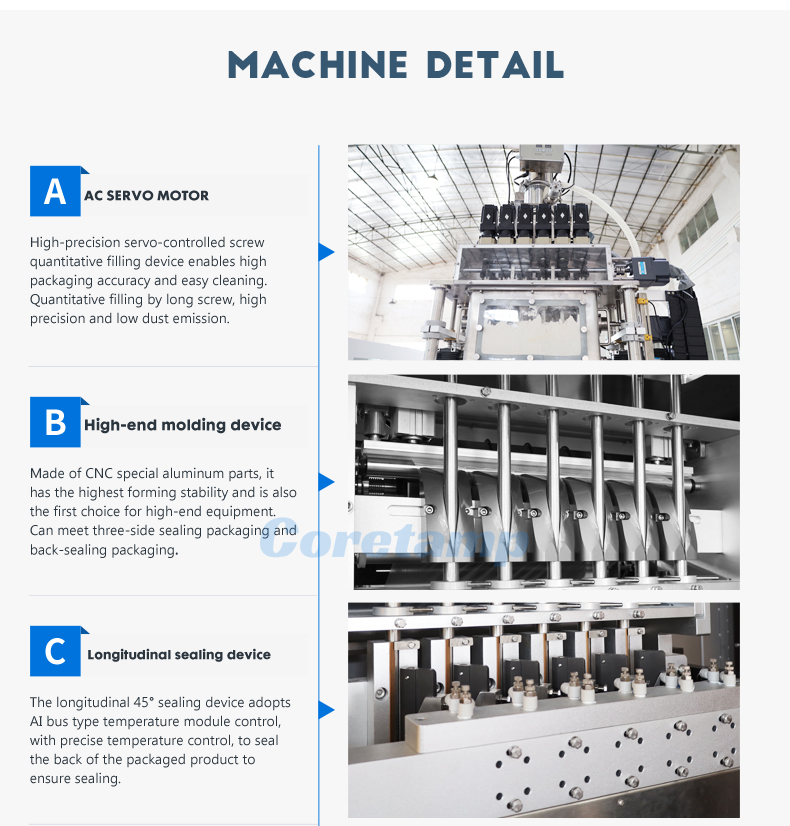

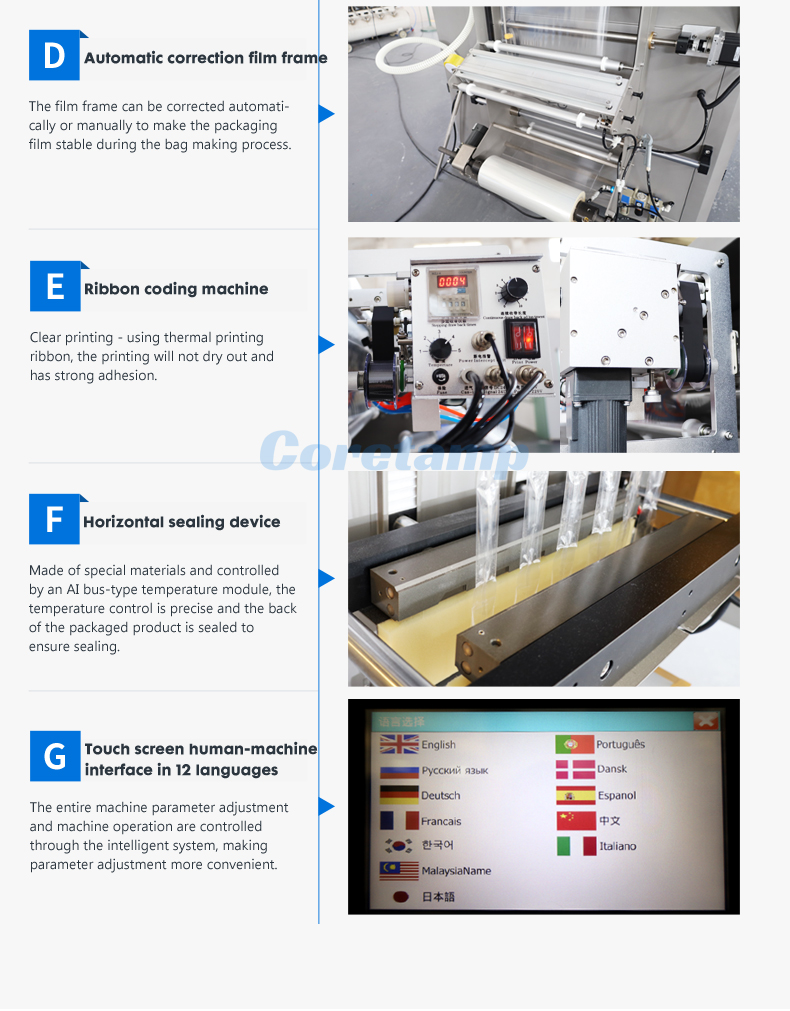

System configuration: Adopting programmable bus system+bus servo, fast response and more accurate

Automatic correction: integral film frame, supply film tension control system to ensure stable bag making

12 common operating languages: easy to operate, with device fault prompts and self diagnostic functions

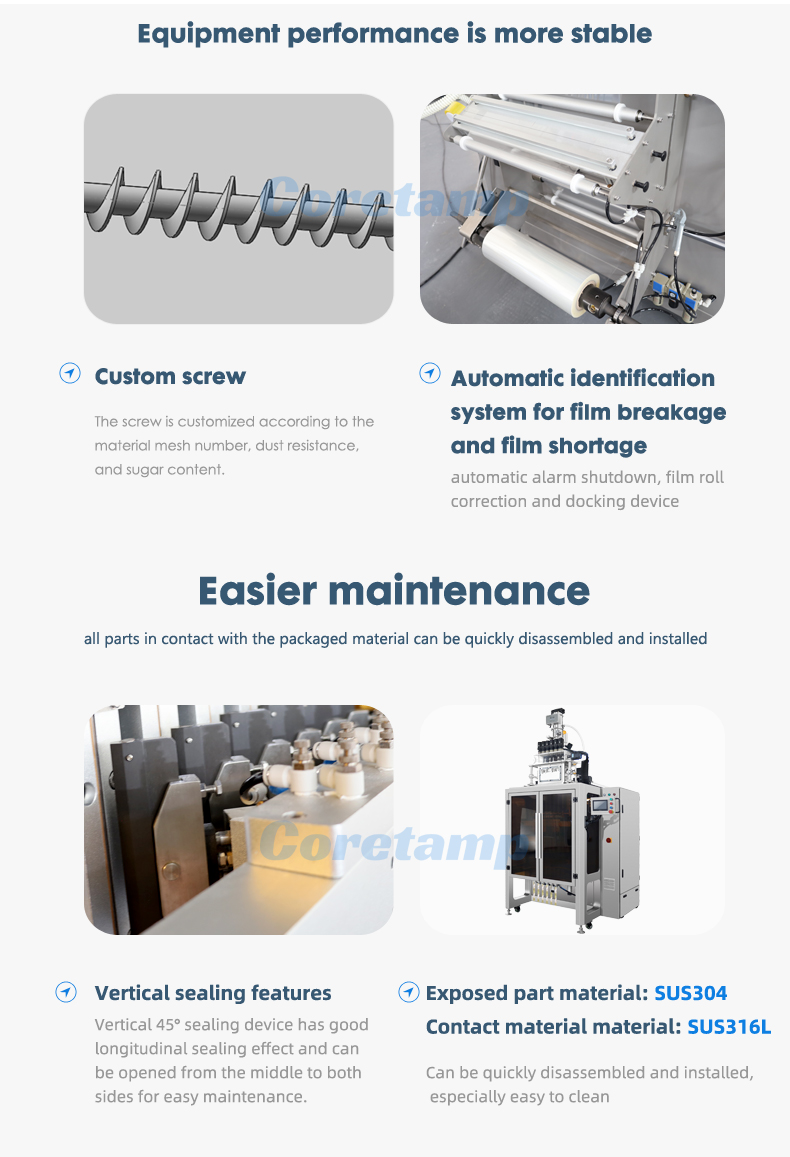

Machine type:

LC500B-6Packaging speed:

20-80 cut/MinPackaging size:

16-50mm(Width) 40-160mm(Length)Machine size:

1200KGMachine material:

316 Stainless Steel

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

© Copyright: 2026 Foshan Coretamp Packaging Machinery Co., Ltd. All Rights Reserved.

IPv6 network supported

Friendly Links :

Coretampack packaging machine manufacturer Weighing Packaging Machine Coretamp packaging machine Longchuan packaging machine Cosmetic Bottle Manufacturer Diaper machine Packing Machine Manufacturer Packaging Labels Manufacturer Carton packing machine manufacturer Magnetic Boxes Pure Water Making Machine gdtsindustry bottle filling machine supplier Aerosol Filling Machines ahvsee Skywinextruder lcknife High RPM Exhaust Fan Tin can canning machine chinafiltermachine Automatic Splicing Machine Schneider BMXDDI3202K Coffee Bag Packing Machine